Aston Origin and Spirit chassis are individually tumbled for up to four hours to give them their unique finish.

The Aston story

Every new Aston Microphone is an event; an industry-shaking rethink of what has gone before. We don’t bring out mics to play catch-up with other brands, we design and build from ground-up, always refusing to believe that world-class sound has to mean dream-shattering price tags. In its short history the brand has won industry awards from all quarters, including the coveted NAMM TEC Award for ‘Best Microphone’ (Aston Stealth 2020).

We are the only mainstream microphone company still manufacturing many of our products in the UK, using locally sourced components where possible. Many of our team are musicians and as such our microphones are infused with this little island’s huge musical heritage. British sound has long been a driver of popular music; from the Beatles to Brit Pop, from Pink Floyd to Punk, the audio gear used - the spitting valve amps and the coal-fired mixing desks - had a sonic character today’s engineers still crave. The digital age may have made most areas of music production easier, quicker and more affordable than ever, but the quest for that sonic holy grail of warmth, granularity and presence has put even more onus on capturing the performance superbly, at source.

The unique finishes of the Origin, Spirit and Starlight make engraving possible.

Breaking the rules

A microphone is more than a functional tool. It is a musical instrument, and the very heart of every recording you will ever make. So when the Aston Microphones brand was first conceived, by a group of eccentrics steeped in that great tradition of British sound, the goal was to build mics that would inspire confidence, and therefore great performances, while delivering pristine, characterful audio to challenge some of the world’s most revered - and expensive - mics, but at a fraction of the cost.

We could only achieve this by breaking most of the ‘rules’ of microphone design and manufacture - rules which have gone largely unquestioned for decades - and starting from scratch. Every new Aston is a mic reimagined, designed by strange-looking folks who eat only pizza and rarely sleep, using materials and manufacturing techniques never previously seen in the mic industry.

Hand-assembly in the UK

Why, for example, do most mics out there share the same fixed gauge mesh head form? These heads break, get dented and don’t work very well as pop filters. By re-thinking this basic area of design on our Origin and Spirit mics we were able to radically improve functionality with our shock-absorbing wave-form spring head and knitted stainless steel mesh, while simultaneously reducing production costs, a saving which we could then use to improve sound performance. Such examples run throughout the range, from Stealth’s four voices and built-in Class A pre amp to Element’s unique Ridyon™ capsule, which combines the best attributes of dynamic, condenser and ribbon technology. You can get the full stories on each product page.

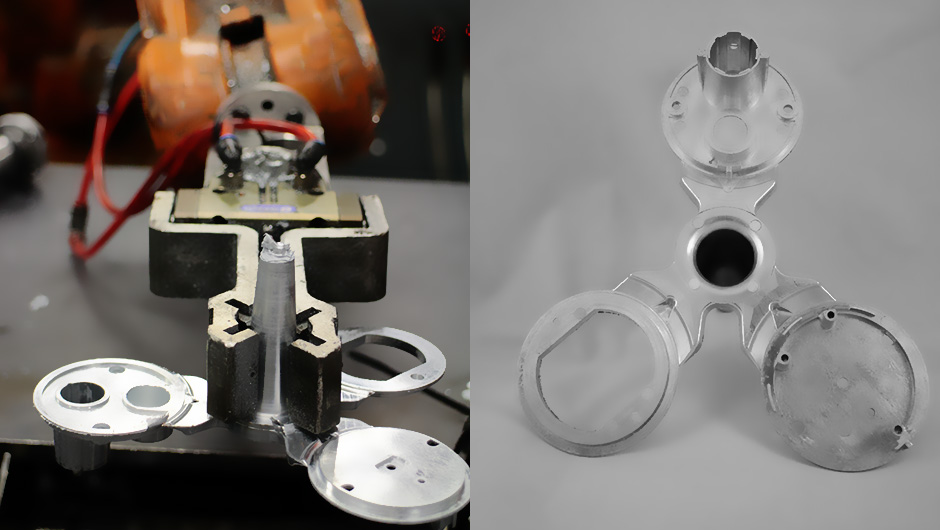

Tooling for Aston's unique LDC end caps.

Innovative, near-indestructible and inexpensive they may be, but what of their all-important sound? How did Aston Microphones quickly become favourites of so many of the world’s top engineers, producers and artists? This, like all aspects of our mics’ development, was down to a complete rethinking of what had gone before…

Meet the Aston 33

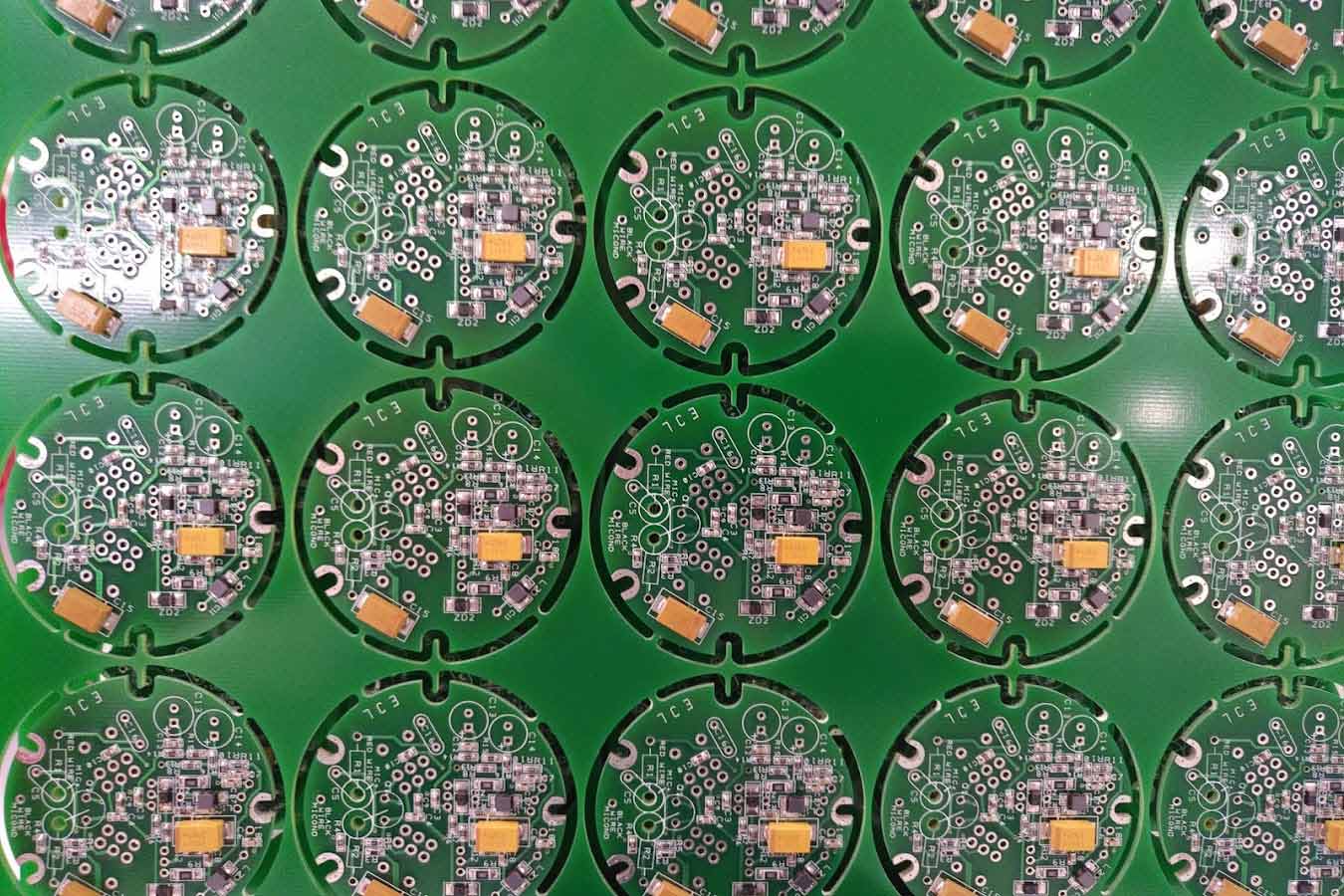

Aston's custom printed circuit boards

Precision hand-soldering

It's a family thing!