Innovation condensed – the Aston Starlight

In our previous article we looked at the numerous electronic innovations which combine to help make the Aston Starlight the most versatile, and best sounding, mic in its class. These include the three completely distinct circuit paths, giving a choice of Vintage, Modern or Hybrid voicings, and the built-in Class 2 laser which makes accurate targeting of sound sources and quick positional recall a breeze.

Some of the manufacturing techniques and materials used for Starlight are equally ground-breaking.

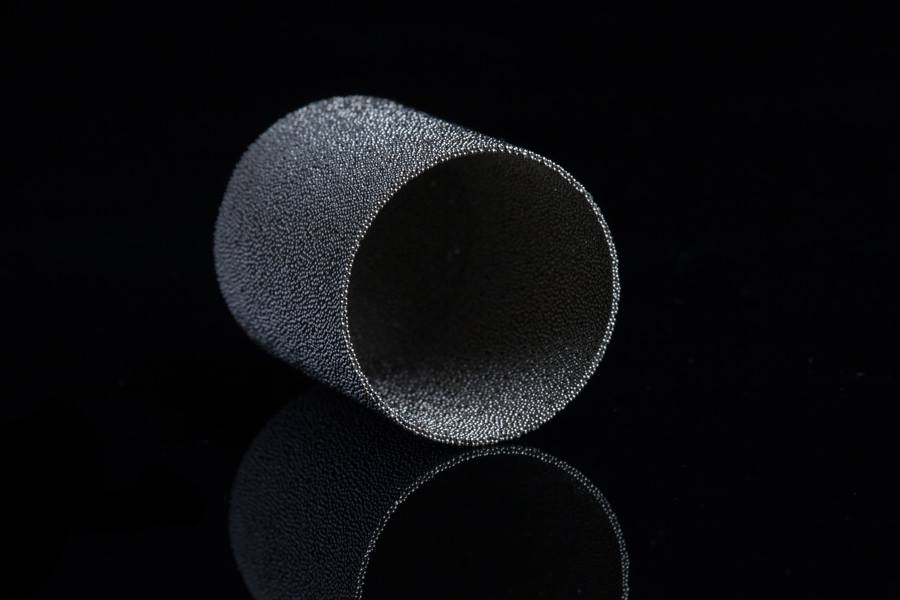

Take the sintered head for example. Sintering in this context is the bonding together of metal spheres by heat and pressure. The process itself is not new but Aston have moved the technology forward significantly. Extensive testing eventually resulted in an optimal combination of average sphere size, head thickness and manufacturing accuracy (down to just a few nanometres) we achieved a mic head which possesses almost perfect acoustic porosity while also being practically indestructible.

Take the sintered head for example. Sintering in this context is the bonding together of metal spheres by heat and pressure. The process itself is not new but Aston have moved the technology forward significantly. Extensive testing eventually resulted in an optimal combination of average sphere size, head thickness and manufacturing accuracy (down to just a few nanometres) we achieved a mic head which possesses almost perfect acoustic porosity while also being practically indestructible.

Drummer, engineer, mixer and songwriter Emre Ramazanoglu (Lily Allen, Sia, Noel Gallagher, Richard Ashcroft, The Prodigy, Tricky, Mark Ronson, Shakira) commented:

“Thanks to that ridiculously solid build quality, you can put Astons in more precarious places than other mics.”

A major additional benefit is that this sintered design produces almost perfectly linear off axis response. i.e there is virtually no HF roll off as you depart from the on-axis plane (the direction the mic is aimed in). In almost all other mics, the sound becomes increasingly coloured by changing frequency response as you move off axis, so you’re not really picking up the true sound of the instrument. With Starlight, you get exactly what is being heard in the room across the entire pick-up pattern of the mic.

Production legend Steve Levine, who has worked with Culture Club, The Clash, The Beach Boys, China Crisis, Gary Moore and many other top artists, told us:

“I've used the Starlights successfully as room mics and they sound absolutely superb.”

At Aston we do not powder-coat our mics like pretty much every other mic manufacturer. Powder coating is easily scratched and adds significant cost to manufacture. The Starlight, like the Origin and Spirit before it, features a custom-finish chassis, individually tumbled for up to four hours to achieve a tough, natural and beautiful finish.

Even the Starlight’s packaging has been thought through from scratch and, like the microphone within, it is beautiful in its simplicity. It is also eco-friendly and cost effective to produce.

Even the Starlight’s packaging has been thought through from scratch and, like the microphone within, it is beautiful in its simplicity. It is also eco-friendly and cost effective to produce.

In neither case - the microphone or the packaging - was cost-cutting part of anyone’s brief. It just turns out that ground-up engineering and manufacturing resulting from close scrutiny of previously unexamined processes and materials happens to also lead to coast savings. Put another way, great design doesn’t necessarily have to be more expensive than bad design.

This also means more of the manufacturing costs of Aston mics goes into the important things; versatility, resilience and most importantly, sound quality.

Win a stereo pair of Aston Starlights here

Learn more about the Aston Starlight microphone here:

https://www.astonmics.com/EN/news-details/Aiming-for-the-stars-the-Aston-Starlight

Find your nearest Aston Microphones dealer here:

https://www.astonmics.com/EN/dealers